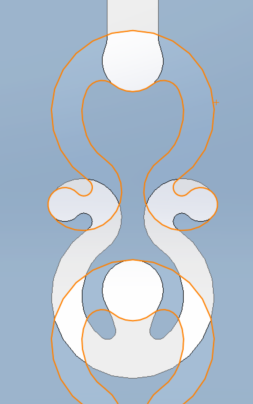

Microchannel mixer

Efficient mixing and heat transfer are achieved by rotating flow in a spiral tube.

| Categoría | Microreactor |

|---|---|

| Marca | SHENSHI Heat Exchanger Manufacturer |

| Application | Medicine, pesticide, gunpowder, dye, environmental |

| Scope of application | Liquid-liquid phase, gas-liquid phase mixing, disp |

| Puerto | Shanghai/Ningbo/Guangzhou |

| forma de pago | L/C, T/T |

| Tiempo de Actualización | 2025/6/23 |

Información Detallada

Microchannel mixer

Efficient mixers with micron channel structures that can quickly mix two or more different fluids together.

Features

1. high mass transfer efficiency: milliseconds to microseconds can be fully mixed, shorten the reaction time, reduce the size of the equipment, while continuous production to improve production efficiency.

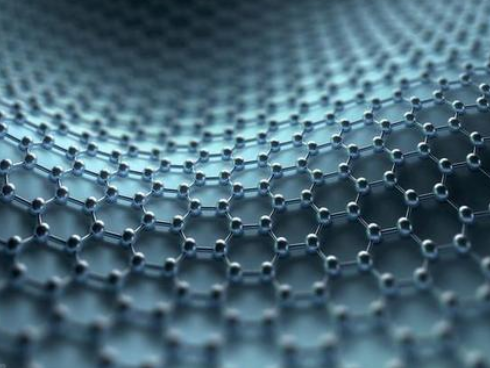

2. miniaturization design: the channel size is very small, only a few microns to several hundred microns, the device is small, easy to integrate and move.

3. accurate control: flow rate, temperature and other parameters can be accurately controlled to ensure the stability and repeatability of the mixing process.

4. high safety: small channel size, small material retention, reduce the risk of material leakage, improve equipment safety.

5. diversity: parts can be modular design, customized design according to different needs, to achieve a variety of mixed processes.

Working principle

Two or more fluids can be mixed quickly and efficiently at the microscale by utilizing the hydrodynamic effects in microchannels. Microchannels are usually only tens to hundreds of micrometers wide and deep, which allows the fluid to flow very fast within the channel, resulting in strong shear forces. This shear force can quickly disperse and mix different kinds of fluids in the microchannel, achieving an efficient mixing effect.

Related industries

Medicine

Optimize drug synthesis with efficient heat and mass transfer characteristics. Help new drug research and development, rapid screening conditions. Achieve continuous production, improve efficiency and reduce costs.

Petrochemical Industry

Efficient heat and mass transfer to optimize critical processes such as heavy oil cracking. It helps the research and development of new processes, and promotes the continuity, efficiency and low-cost of petrochemical production.

Pesticide

Strengthen the synthesis efficiency and product quality, accelerate the research and development of new pesticides, promote the continuity and automation of pesticide production, and reduce costs.

Dye

Optimize the dye synthesis process, strengthen the color mixing uniformity, and help the development of new dyes; Improve the continuity and efficiency of dye production.

Essence And Fragrance

Efficient synthesis of complex aroma ingredients, precise allocation of aroma ratio, accelerate new product development; Efficient automation of production processes.

Advanced Material

Promote the synthesis of nanomaterials, strengthen the uniform mixing of material components, and help the rapid development of new materials.

Escriba su mensaje por favor

¿Busca una solución confiable de gestión térmica baja en carbono? Ofrecemos asesoramiento sobre productos, soporte técnico y servicios personalizados con rapidez. Contáctenos para más información.

- Nombre

- Teléfono

- *Título

- *Contenido